Servo Hoist Systems

Knight Servo Hoist Systems are user-friendly, Intelligent Assist Devices (IAD) that provide controlled transfers of workloads by enhancing the precision and speed needed for the application. As an extension of an operator’s natural movement, this technology greatly improves the accuracy and repeatability of the application. Additionally, Knight has integrated their servo systems with the advancing technology of Industry 4.0. With this development, functionality of the hoists can be monitored virtually from anywhere within a production setting.

As a standard feature of Servo Hoists, the patented Safety Drop Stop, or “SDS”, (patent#: 10,099,904) acts as a redundant precautionary measure. Two high cycle chains travel along-side one another: one chain carrying the load, while the other is there for safety in case of a chain failure.

The inherent benefits of Knight’s Servo Systems include: elimination of wasted motion, reduced reaction time, and minimal effects of inertia on heavy loads. Knight Servo Systems enable an operator to simply grasp the handle and move the load with instantaneous response, another signature feature called “Float Mode”. No button pushing is required.

Standard or custom options are available to allow for various programmed product functions. Contact a Knight global representative for more information.

General Information

+Features

- Load Capacity: Up to 2,000 lbs. [907kg].

- Variable speeds: Up to 241 fpm [73.5mpm].

- 240 VAC, Single Phase, 50/60 Hz.

- H5 Rated (continuous duty cycle).

- “SDS” Safety Drop Stop chains.

- Knight’s Unique “Float” Mode.

- Fail-Safe Brake.

- Chain Driven.

- Load Sensing.

- I/O Capabilities.

- Virtual Travel Limits.

- Illuminated Run-Stop Button.

- LED Status/ Fault Indicators.

Benefits

- Various Chain Lengths available.

- Optional Remote Pendant or Remote Handle.

- Fully Programmable.

- Multiple attachment choices.

- Industry Standard 240VAC Single Phase or 480 VAC 3 Phase Input power

- Programmable Speed Reduction Zones.

Specifications

+Servo System Configurations

- Safety Drop Stop Servo Hoist (Standard).

- D-Series Servo Hoist.

- SDS Speed Hoist.

- Twin Chain Safety Drop Stop.

- Twin Chain Dual Motor Safety Drop Stop.

- Articulating Arm (Overhead Carriage or Floor Mounted).

- Extension Arm (Overhead Carriage or Floor Mounted).

- Extension Boom Arm (Overhead Carriage or Floor Mounted).

Cont’d.

- Vertical Arm (Overhead Carriage or Floor Mounted).

- Vertical Roller Arm (Overhead Carriage or Floor Mounted).

- VFD Electric Tractor.

- Servo “X” Tractor with “Z” Lift Hoist.

- Servo “X/Y” Tractor.

- Servo “X/Y” Tractor with “Z” Lift Hoist.

- Servo “XX/Y” Tractor with “Z” Lift Hoist.

Controls & Accessories

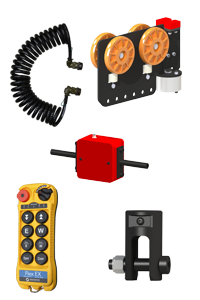

+ Servo Hoist Control Handles and Modules

Servo Hoist Control Handles and Modules

Knight Global provides multiple models and configurations of Servo Hoist Control Handles. We offer our a line of Electric Control Handles, fully programmable Analog Inline Control Handles and fully programmable.

Servo Hoist Attachments

Knight’s Servo Hoist attachment accessories offer various workstation rail load trolleys, fixture attachment options and custom designed End Effectors. Knight Global also offers many electrical supply and mounting choices for the the Knight Servo Hoist systems.

Servo Hoist Replacement Chain Kits

The Knight Servo Hoist patented Chains and Roller Chains are available in a full replacement kits that provide everything needed to replace worn out or broken chains. The working load limits of our different chains vary and depend in the chain’s thickness.

Knight’s Servo Hoist chain is a custom grade lifting chain specially treated to increase the life of the chain by up to 300%.

Why Choose A Knight Servo?

+Safety

The patented Safety Drop Stop “SDS” feature makes Knight’s Servo Hoists the safest in the industry. A redundant safety chain travels alongside the load chain to protect from the dropping of a load in the event of chain failure.

Intuitive

Servo systems are intuitive and require little to no worker training. The operator will experience Instantaneous Response of the system, when the handle is grasped (Float Mode).

Programmable

The user can control lifting speeds, including setting acceleration and deceleration rates. The system monitors the weight at all times and can quickly react to loaded and unloaded conditions. Virtual limits can be programmed (with Knight’s Servo Studio Software) to set up work envelopes and slow down zones. Additional I/O comes standard on all systems to assist in interlocking with added motions or to establish safe zones.

Powerful

Servos systems assist your natural movements, by combining safety and ergonomics; it makes heavy loads feel weightless.

Durable

Chain is more durable when balancing weights in excess of 250 lbs. [113kg] and/ or when high cycle rates are encountered. Cable has a greater tendency to fray or “birdcage”. Chain makes this system virtually maintenance free.

Fast

Maximum Servo Hoist lifting speeds up to 241 fpm (73.5mpm) and maximum Servo Tractor travel speeds up to 174 fpm (53.2mpm). By controlling your work envelopes and precise positioning you will decrease cycle times.

Productive

All of the Servo Hoist features here add up to increased productivity, improved ergonomics for workers, and a safer work environment.

Selecting a Servo System

+KSHS Series Servo Hoist Control Configurations

When Selecting a Knight Servo Control System there are many factors to determine before selecting the appropriate configuration. To assist in determining the correct configuration for your application you will need to print, fill-out and submit this configuration sheet to Knight’s Estimating Department. If you need any assistance or more information, please contact our Servo Department.

Determining your Application Process

- System configuration – The KSHS Series comes as a complete system with the option of an inline handle or a remote handle. Most systems include only one or the other, not both.

- Lifting Capacity – Include your fixture and part weight when determining this capacity.

- System Style – Single chain with Safety Drop Stop (SDS) chain.

- Coil Cable Length –

- Rail height – Know your hang point. Depending on your system’s configuration, the distance from the bottom of the rail to the load hang point on a servo can be as much as 4 ft.

- Determine your pick-up and drop-off heights. These are very important and can affect your stack-up and rail height.

- Use the application drawing to determine your stack up.

- Choose your coil cable.

- Trolley – determine your hang point (this can not be a single point) and choose your trolley. If you have a trolley already, an EBD1127 adaptor plate will be provided at no extra charge.

- Hoist Control Set-up – Determine how you are going to control your up/down movement and which configuration best fits the application. Please keep the following in mind:

- Choosing the Inline Handle:

- Can the operator reach the handle in the upmost position?

- Will the operator be safe using the inline handle with being so close to the load?

- Can the operator always reach the Run-Stop button regardless of the height of the load?

- Be sure you identify any additional cables when choosing your configuration.

- The LMM to the OCI cable.

- The fixture handle to the OCI cable.

- Choosing the Inline Handle:

- Plant Power – Servo systems operate on 240VAC, 1phase. If the plant that this servo is being installed in only has 480VAC, you will need to order one of our 480VAC/ 240VAC transformer disconnect options.