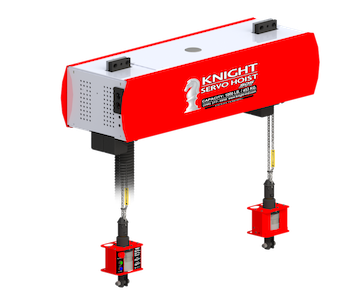

Twin Chain Servo Hoist

Knight’s KSHTC Twin Chain Servo Hoist and KSHTCDM Dual Motor Twin Chain Servo Hoist are Intelligent Assist Devices (IAD) that enable an operator to precisely locate or float a load in the “Z” direction (vertical axis) with speed and reliability. This design specifically helps to control and balance unwieldy or long parts.

Both Twin Chain Servo Hoists are equipped with the “SDS” (Safety Drop Stop) feature. KSHTC’s two (2) twin chains are mechanically linked together so they operate as one unit. KSHTCDM’s two (2) twin chains are controlled in conjunction with each other. Each motor is electronically synced together with an option of a (LMM) Load Monitoring Module with Operator Controlled Interface or a (LMM) Load Monitoring Module with Pass Through Interface.

The Twin Chain Servo Hoist allows for many application solutions due to the various programmability features. They enable an operator to simply grasp the handle and move the load, eliminating push buttons. Traditional hoists require the operator to push buttons in order to initiate a natural ergonomic motion.

Knight’s Servo Hoist technology becomes an extension of an operator’s natural movements and greatly improves accuracy, responsiveness and repeatability; which increases overall safety, productivity and quality. The inherent benefits include: eliminating wasted motions, reduced reaction times, and minimal effects of inertia with heavy loads.

Twin Chain Servo Hoist Series Model Numbers:

KSHTC250S-2401 & KSHTC500S-2401

Twin Chain Dual Motor Servo Hoist Series Model Numbers:

KSHTCDM700S-4803, KSHTCDM1500S-4803, KSHTCDM2000S-4803 & KSHTCDM4000S-4803

To see examples of custom Servo applications designed by Knight, visit our Gallery.

General Information

+Mechanical

- Speeds: Up to 196 ft. per min. [60mpm].

- KSHTCDM – Dual Motor Control.

- Standard Chain Center Point Distances: 24 in. [609mm] – 36 in. [914mm]. (Widths over 36 in. are custom)

- Safety Rating of 125%.

- Fail Safe Brake.

- Knight’s Patented Chains, for longer life.

- Chain Length, Unlimited (18 ft. Standard).

- Sealed Worm Style Gearbox.

- H5 Rated (Continuous Duty Cycle).

Software

- Programming and Diagnostic Communication Ports.

- Virtual Travel Limits.

- Speed Reduction Zones.

- Impact Limiting.

- Active Dampening.

- Standard Float Mode.

- Programmable Overload Capability.

Electrical

- Industry Standard 24 VDC, 2 AMP power is available for custom tooling such as: Clamps, Vacuum Cups, Switches, Proximity Limits, Lights, etc.

- Illuminated Run/ Stop Button.

- 240 VAC, Single Phase 50/60 Hz.

- Load Sensing, Pay Load and Handle Load.

- I/O Capabilities:

- (16) Inputs/ (8) Outputs

- (8) Inputs/ (4) Outputs are free for interface controls.

- LED Status Indicators, Green and Blue Lighted Push buttons.

- LED Fault Indicators, Illuminated Run/ Stop Button, Twist to Release.

- Optional Remote Pendant or Remote Handle.

Twin Chain Servo Hoist Series Specifications

+Twin Chain Servo Hoist Series

| Model Number | Capacity lbs. [kg] | Max Speed [fpm/mpm] | Voltage / Phase |

|---|---|---|---|

| KSHTC250S-2401 | 250 lbs. [113kg] | 196.85 fpm. [60mpm] | 240 / 1 Phase |

| KSHTC500S-2401 | 500 lbs. [226kg] | xxx.xx fpm. [mpm] | 240 / 1 Phase |

Twin Chain Dual Motor Servo Hoist Series Specifications

+Twin Chain Dual Motor Servo Hoist Series

| Model Number | Capacity lbs. [kg] | Max Speed [fpm/mpm] | Voltage / Phase |

|---|---|---|---|

| KSHTCDM700S-4803 | 700 lbs. [317kg] | xx.xx fpm. [mpm] | 480 / 3 Phase |

| KSHTCDM1500S-4803 | 1500 lbs. [680kg] | 123.03 fpm. [37.5mpm] | 480 / 3 Phase |

| KSHTCDM2000S-4803 | 2000 lbs. [907kg] | 41.01 fpm. [12.5mpm] | 480 / 3 Phase |

| KSHTCDM4000S-4803 | 4000 lbs. [1814kg] | xxx.xx fpm. [mpm] | 480 / 3 Phase |

Options

+KSHTC/ KSHTCDM Servo Hoist

When Selecting a Knight Servo Control System there are many factors to determine before selecting the appropriate configuration. To assist in determining the correct configuration for your application you will need to Print, Fill-out and Submit the configuration sheet below to Knight’s Estimating Department. If you need any assistance or need more information, Contact our Servo Department.

Determining your Application Process

- System configuration – The KSHTC / KSHTCDM Series comes as a complete system with the option of an inline handle or a remote handle. One or the other comes with the system, not both.

- Lifting Capacity – Include your fixture, and part weight when determining a size.

- System Style – SDS (safety and load) chains

- Coil Cable Length:

- Rail height – Know your hang point, from the bottom of the rail to the load hang point on a servo can be as tall as 4 ft., depending on your system configuration.

- Determine your pick-up and drop-off heights, this is very important and can affect your stack-up and rail height.

- Use the application drawing to determine your stack up.

- Choose your coil cable.

- Trolley – determine your hang point (this can not be a single point) and choose your trolley. If you have a trolley already, an EBD1127 adaptor plate will be provided at no extra charge.

- Hoist Control Set-up – Determine how your going to control your up/ down movement, and which configuration best fits the application; keeping the following in mind.

- Choosing the Inline Handle:

- Can the operator reach the handle in the upmost position?

- Will the operator be safe using the inline handle with being so close to the load?

- Can the operator always reach the run-stop button?

- Be sure you identify the any additional cables when choosing your configuration.

- The LMM to the OCI

- The fixture handle to the OCI

- Choosing the Inline Handle:

- Plant Power – Servo systems operate on 230VAC 1phase. If the plant that this is being installed in only has 480VAC, you will need to order one of our 480VAC/ 240VAC transformer disconnect options.

Videos

+*Applications Compilation

*KSAA1003 Chain Wear Gauge

*SDS Servo Hoist Preventative Maintenance

*Servo Hoist XYZ System – Seat Install

SDS Servo Hoist Chain Replacement Instructions

Servo System Applications

Accessories