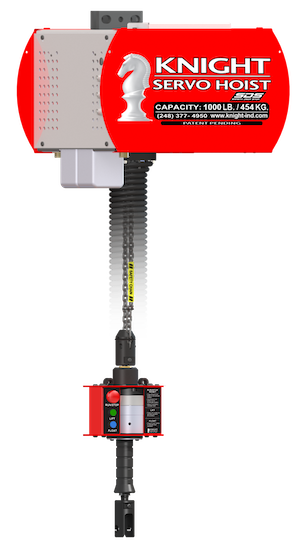

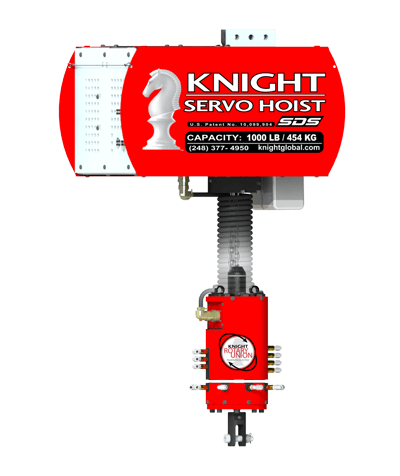

Safety Drop Stop “SDS” Servo Hoist

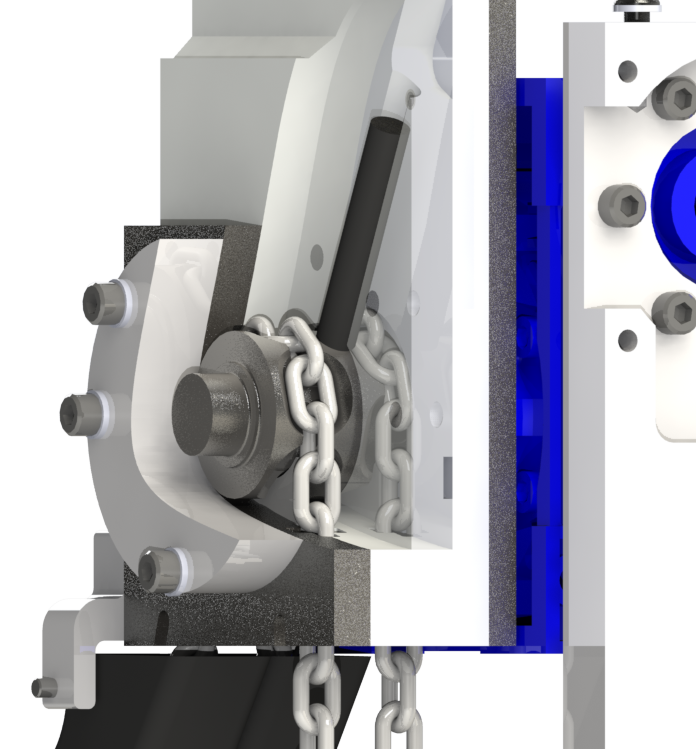

Knight is leading the industry with its next-generation KSHS Safety Drop Stop Servo Hoist series (Patent No. 10,099,904) – the safest, most intelligent hoist in the world. The KSHS Series includes our patented “Safety Drop Stop” (SDS) feature and has redundant chains – one that carries the load and another that travels along for safety.

This series has added features to its Intelligent Assist Device (IAD) that give the operator improved precision to locate or float a load in the “Z” direction (vertical axis).

Our KSHS Series allows for many application solutions due to its various programmable features and unlimited I/O. Unlike traditional hoists that require the operator to push buttons, our SDS Servo Hoist enables an operator to simply grasp the handle and move the load, eliminating push buttons altogether.

Additionally, the SDS Servo Hoist includes a drop-in graphite stick inside of the gear tower to ensure lubrication of the chains. Replacement sticks can be ordered separately.

Knight’s Servo Hoist technology becomes an extension of an operator’s natural movements and greatly improves accuracy, responsiveness and repeatability; which increases overall safety, productivity and quality. The inherent benefits include: eliminating wasted motions, reduced reaction times, and minimal effects of inertia on heavy loads.

SDS Servo Hoist Series Model Numbers:

KSH250S-2401, KSH350S-2401, KSH500S-2401, KSH750S-2401 & KSH1000S-2401

To see examples of custom Servo applications designed by Knight, visit our Gallery.

General Information

+Mechanical

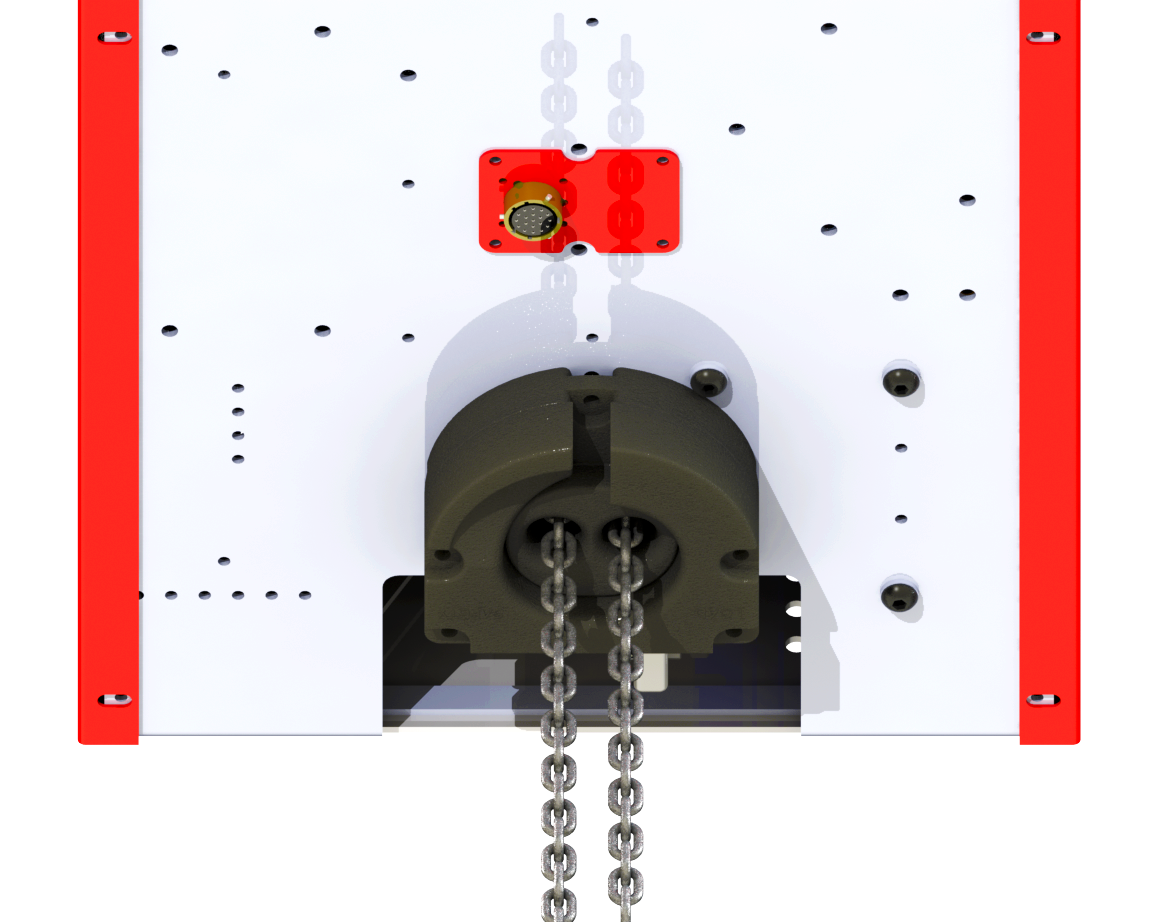

- Redundant chain design for safe operation:

- Load Chain: Carries the load.

- Safety Chain: Rides along for redundancy and safety.

- Speeds: Up to 241 ft. per min. [60mpm].

- Safety Rating of 125%.

- Fail-Safe Brake.

- Knight’s Patented Chain, for longer life.

- Chain Length, Unlimited (12-18 ft. Standard).

- Sealed Worm Style Gearbox.

- H5 Rated (Continuous Duty Cycle).

- Chain Lube Stick

Software

- STO – Safe Torque Off.

- Enhanced User Interface (UI).

- Ethernet Connection.

- Programming and Diagnostic Communication Port.

- Virtual Travel Limits.

- Speed Reduction Zones.

- Impact Limiting.

- Active Dampening.

- Knight’s Unique Float Mode.

- Programmable Overload Capability.

Electrical

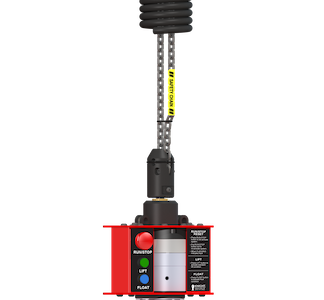

- Industry Standard 24 VDC, 2 AMP power is available for custom tooling such as: Clamps, Vacuum Cups, Switches, Proximity Limits, Lights, etc.

- Illuminated Run/ Stop Button.

- Enable trigger, for quicker response.

- 240 VAC, Single Phase 50/60 Hz.

- Load Sensing, Pay Load and Handle Load.

- I/O Capabilities:

- (4) Analog Inputs/ (4) Analog Outputs.

- (24) Inputs or Outputs, configurable.

- (8) Dedicated Inputs.

- Expansion I/O: Ethernet, unlimited.

- LED Status Indicators: Green and Blue Lighted Push buttons.

- LED Fault Indicators: Illuminated Red Run-Stop Button, Twist to Release.

- Optional Remote Pendant or Wireless Remote Control.

SDS Servo Hoist Series Specifications

+SDS Servo Hoist Series

| Model Number | Capacity lbs. [kg] | Max. Speed fpm. [mpm] | Voltage / Phase |

|---|---|---|---|

| KSH250S-2401 | 250 lbs. [113kg] | 196.85 fpm. [60.0mpm] | 240 / 1 Phase |

| KSH350S-2401 | 350 lbs. [158kg] | 241.00 fpm. [73.5mpm] | 240 / 1 Phase |

| KSH500S-2401 | 500 lbs. [226kg] | 98.43 fpm. [30.0mpm] | 240 / 1 Phase |

| KSH750S-2401 | 750 lbs. [340kg] | 123.03 fpm. [37.5mpm] | 240 / 1 Phase |

| KSH1000S-2401 | 1,000 lbs. [453kg] | 82.02 fpm. [25.0mpm] | 240 / 1 Phase |

| KSH2000S-2401 | 2,000 lbs. [907kg] | 37.50 fpm. [11.43mpm] | 240 / 1 Phase |

Videos

+*Applications Compilation

*Knight Rotary Union – Electric / Pneumatic

*KSAA1003 Chain Wear Gauge

*New Safety Drop Stop “SDS” Servo Hoist

*SDS Servo Hoist Preventative Maintenance

*Servo Hoist Extension Arm

*Servo Hoist XYZ System – Seat Install

SDS & Traditional Hoist Comparison

SDS Servo Hoist Chain Replacement Instructions

Servo System Applications

Accessories