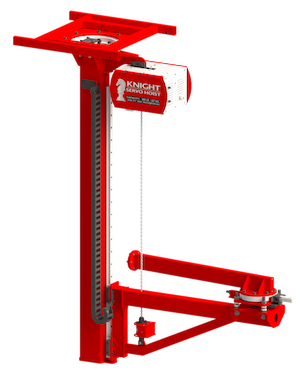

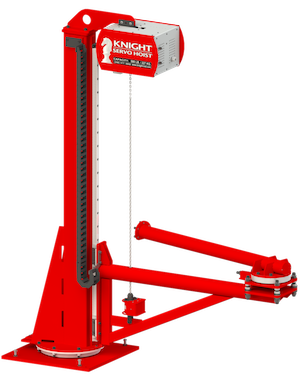

Vertical Servo Arms

Knight KSHVA Overhead Carriage Mounted and KSHVAA Floor Mounted Vertical Servo Arms are Intelligent Assist Devices (IAD) that enable an operator to reach outside the area directly below a rail system and to precisely locate or float loads in the “Z” direction (vertical axis) with speed and reliability. The Vertical Servo Arms allow for a non-linear overhead varied reach within a work cell or station.

Knight’s Servo Hoist technology becomes an extension of an operator’s natural movements and greatly improves accuracy, responsiveness and repeatability; which increases overall safety, productivity and quality. The inherent benefits include: eliminating wasted motions, reduced reaction times, and minimal effects of inertia with heavy loads.

Product does not come as shown. Overhead carriage sold separately. Contact a Knight representative for more information.

Note: All capacities exclude the weight of the jib and the boom.

Lifting capacities are calculated starting from the load cell (end of the chain).

Overhead Carriage Mounted Servo Hoist Vertical Arm Series Model Numbers:

KSHVA250-2301, KSHVA350-2301, KSHVA750-2301 & KSHVA1000-2301

Floor Mounted Servo Hoist Vertical Arm Series Model Numbers:

KSHVAA250-2301, KSHVAA350-2301, KSHVAA750-2301 & KSHVAA1000-2301

General Information

+Mechanical

- Speeds: Up to 241 ft. per min. [60mpm].

- Floor Mounted Pedestal Heights: 8 ft. [2.4m] – 10 ft. [3.0m].

- Safety Rating of 125%.

- Fail Safe Brake.

- Knight’s Patented Chain, for longer life.

- Chain Length, Unlimited (18 ft. Standard).

- Sealed Worm Style Gearbox.

- H5 Rated (Continuous Duty Cycle).

- (1) EBA1393 Precision Gauge Included.

Software

- Programming and Diagnostic Communication Ports.

- Virtual Travel Limits.

- Speed Reduction Zones.

- Impact Limiting.

- Active Dampening.

- Standard Float Mode.

- Programmable Overload Capability.

Electrical

- Industry Standard 24 VDC, 2 AMP power is available for custom tooling such as: Clamps, Vacuum Cups, Switches, Proximity Limits, Lights, etc.

- Illuminated Run/ Stop Button.

- 240 VAC, Single Phase 50/60 Hz.

- Load Sensing, Pay Load and Handle Load.

- I/O Capabilities:

- (16) Inputs/ (8) Outputs

- (8) Inputs/ (4) Outputs are free for interface controls.

- LED Status Indicators, Green and Blue Lighted Push buttons.

- LED Fault Indicators, Illuminated Run/ Stop Button, Twist to Release.

Vertical Servo Arm Series Specifications

+Overhead Carriage Mounted Vertical Servo Arm Series

| Model Number | Capacity lbs. [kg] | Max. Speed [fpm/mpm] | Voltage / Phase |

|---|---|---|---|

| KSHVA250-2301 | 250 lbs. [113kg] | 196.85 fpm. [60.0mpm] | 240 / 1 Phase |

| KSHVA350-2301 | 350 lbs. [158kg] | 241.00 fpm. [73.5mpm] | 240 / 1 Phase |

| KSHVA750-2301 | 750 lbs. [340kg] | 123.03 fpm. [37.5mpm] | 240 / 1 Phase |

| KSHVA1000-2301 | 1,000 lbs. [453kg] | 82.02 fpm. [25.0mpm] | 240 / 1 Phase |

Floor Mounted Vertical Servo Arm Series

| Model Number | Capacity lbs. [kg] | Max. Speed [fpm/mpm] | Voltage / Phase |

|---|---|---|---|

| KSHVA250-2301 | 250 lbs. [113kg] | 196.85 fpm. [60.0mpm] | 240 / 1 Phase |

| KSHVA350-2301 | 350 lbs. [158kg] | 241.00 fpm. [73.5mpm] | 240 / 1 Phase |

| KSHVA750-2301 | 750 lbs. [340kg] | 123.03 fpm. [37.5mpm] | 240 / 1 Phase |

| KSHVA1000-2301 | 1,000 lbs. [453kg] | 82.02 fpm. [25.0mpm] | 240 / 1 Phase |

Note: All capacities exclude the weight of the jib and the boom.

Lifting capacities are calculated starting from the load cell (end of the chain).

Videos

+*Applications Compilation

*Servo Hoist XYZ System – Seat Install

*XYZ Servo System – IP Install

Battery Lift and Install Assist

Servo System Applications

Transmission Transfer Case Lift Assist

Accessories