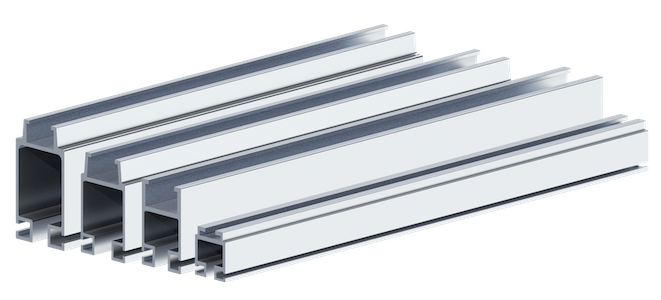

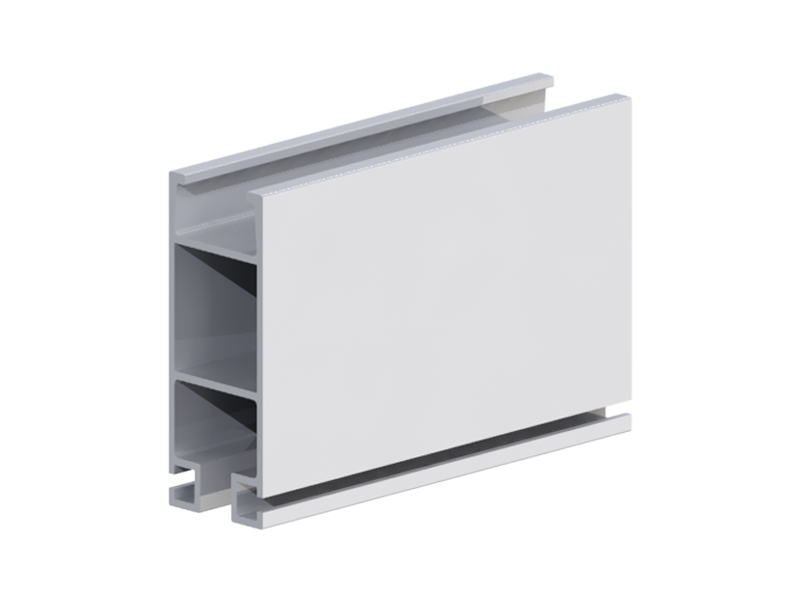

Enclosed Track Aluminum Rail Series

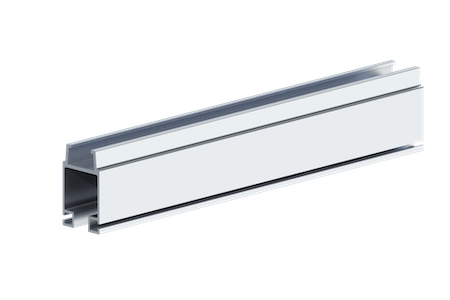

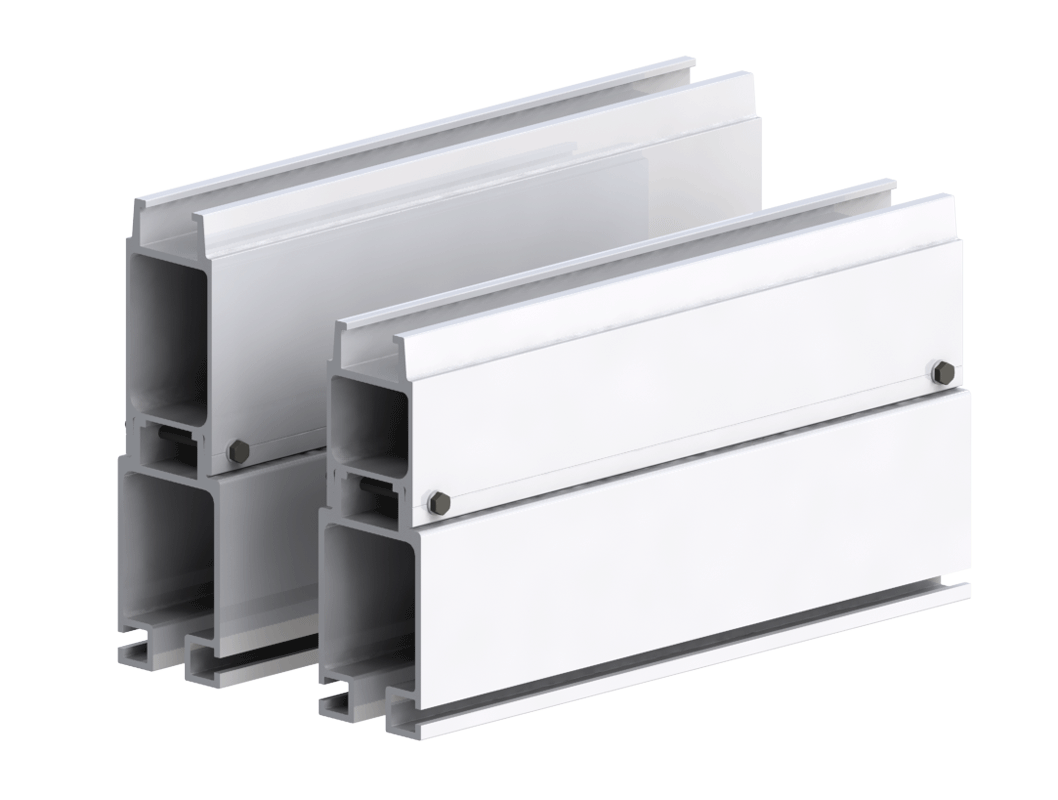

Knight’s RAD4110, RAD6110 and RAD7510 Aluminum Rail Series has an enclosed track design that is extruded from a lightweight, high-strength aluminum alloy. The lightweight aluminum rail eases installation and reduces overhead requirements. The enclosed Series Rail is the ideal solution, whether your load is located directly under the system or cantilevered off to the side. This series, combined with nylon trolley wheels, provides the lowest rolling resistance in the industry.

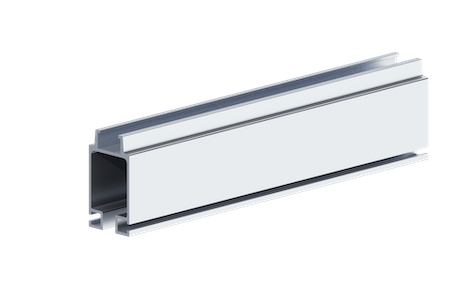

For capacities greater than 3000 lbs., a Backer rail can be integrated into Knight’s RAD7510 Rail. This allows for greater capacities to be achieved. Either 6″ (RAA4438) or 8″ (RAA4439) Backers are available. See chart below for specific capacities.

Knight also has implemented the RAD8110 Aluminum Rail Series to compete with European-style rails while offering a more robust profile. This rail style uses most accessories for the RAD4110 series. See charts below for specific capacities.

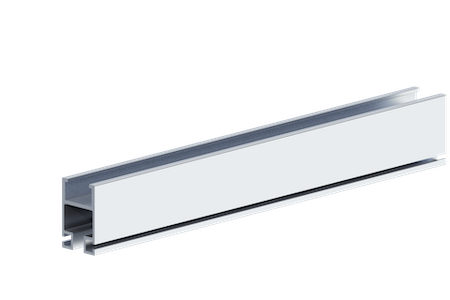

The TR2000 Series Aluminum Rail is a streamlined design ideal for applications under 550 lbs/ft. [249.5 kg/m] capacity. This innovative system allows for festooning trolleys and plant utilities to be attached to the main line rail system, allowing for more travel. Application types can include: light duty weld guns, work benches and stations, filter/regulator/lubrication (FRL), festooning, light fixtures, weld curtains, etc.

General Information

+Features

- Mechanical Properties: ASTM B221 6005-T5 Series Aluminum.

- Multiple Overhead and Floor Mounted Configurations.

- Supports Trolleys, End Trucks and Hangers.

- TR2000/RAD4110/RAD6110 Rail Lengths:

Up to 25 ft. [7.6m] without Splices. - RAD7510 Rail Lengths: Up to 30 ft. [9.1m] without Splices.

Benefits

- Transfer Loads in the “X” and “Y” Directions.

- Multiple Pre-Assembled Accessories.

- Accessories can be positioned along the rail, no welding required.

- Load Trolleys and End Trucks are designed for cantilevered and direct load applications.

- All Hangers and End Trucks are designed to prevent binding of bridges and runways.

Rail Series Specifications

+Enclosed Aluminum Rail Series

| Series | Max. Capacity | Product Weight |

|---|---|---|

| TR2000 | 550 lbs. [250kg] | 2.3 lbs/ ft. [3.33kg/m] |

| RAD4110 | 1,100 lbs. [499kg] | 4.3 lbs/ ft. [6.23kg/m] |

| RAD6110 | 1,600 lbs. [725kg] | 5.2 lbs/ ft. [7.7kg/m] |

| RAD7510 | 3000 lbs. [1,360kg] | 8.3 lbs/ ft. [12.02kg/m] |

| RAD8110 | 4000 lbs. [1814kg] | 6.4 lbs/ ft. [2.90kg/m] |

TR2000 Capacity Chart

+Rail Capacities

| Hanger Span | Deflection Criteria | ||||

|---|---|---|---|---|---|

| 1:350 Capacity* | 1:450 Capacity* | ||||

| ft | m | lbs | kg | lbs | kg |

| 5 | 1.52 | 550 | 250 | 470 | 213 |

| 6 | 1.83 | 400 | 181 | 340 | 154 |

| 7 | 2.13 | 350 | 159 | 295 | 134 |

| 8 | 2.45 | 250 | 113 | 210 | 95 |

| 9 | 2.74 | 200 | 90 | 170 | 77 |

| 10 | 3.05 | 175 | 80 | 150 | 68 |

| 11 | 3.35 | 160 | 72 | 135 | 61 |

| 12 | 3.66 | 135 | 61 | 115 | 52 |

| 13 | 3.96 | 125 | 57 | 105 | 47 |

| 14 | 4.27 | 115 | 52 | 95 | 43 |

| 15 | 4.57 | 90 | 40 | 75 | 34 |

| 16 | 4.88 | 75 | 34 | 65 | 30 |

| 17 | 5.18 | 65 | 30 | 55 | 25 |

*Due to Ergonomic considerations, each rail span distance is tested to determine the maximum single point load required to achieve a predetermined deflection based on a ratio of 1:350 (1” of deflection for each 350” of length) or 1:450 (1” of deflection in 450” of length).

For purposes of estimating approximate ergonomic force requirements, the following

formula may be used:

Fs = frictional force = 0.009 x total mass. This indicates the maximum effort (in lbf) required to overcome inertia. Effort required to sustain movement, Fk (dynamic friction force) is generally 0.35 times the frictional force.

E.g.;

Fs = 0.009 x 250 lbs. (113.4 kg) mass = 2.25 lbf (0.9 kg) required to overcome inertia.

Fk = 0.009 x 250 lbs. (113.4 kg) mass x .35 = .79 lbf (0.36 kg) required to sustain movement.

Cantilevered Capacities (based on 8ft. hanger span)

| Cantilevered | Deflection Criteria | ||||

|---|---|---|---|---|---|

| 1:350 Capacity* | 1:450 Capacity* | ||||

| ft | m | lbs | kg | lbs | kg |

| 1 | .30 | 100 | 45 | 75 | 34 |

| 2 | .61 | 50 | 23 | 35 | 16 |

Elastic deformation: This type of deformation is reversible. Once the forces are removed, the object returns to its original shape. The elastic range ends when the material reaches its yield strength. At this point deformation begins.

Plastic deformation: This type of deformation is not reversible. Once an object reaches this point, it will not return to its original shape. Plastic deformation ends with the fracture of the material.

Knight Global follows material handling industry standards in determining the capacity ratings for enclosed track overhead workstation crane systems. Each component (e.g. rail, hangers, trolleys, etc.) is individually tested to establish its ultimate failure point. From this number, a safe working load is then assigned to the component. Each rail span length is then tested to determine the maximum single point load required to achieve a predetermined deflection based on a 1:350 ratio (1″ of deflection for each 350″ of length). The recommended rated capacity chart is based upon single point loading for the listed spans.

RAD4110 Capacity Chart

+Rail Capacities

| Hanger Span | Deflection Criteria | ||||

|---|---|---|---|---|---|

| 1:350 Capacity* | 1:450 Capacity* | ||||

| ft | m | lbs | kg | lbs | kg |

| 5 | 1.52 | 1100 | 499 | 950 | 431 |

| 6 | 1.83 | 1100 | 499 | 950 | 431 |

| 7 | 2.13 | 1050 | 476 | 875 | 397 |

| 8 | 2.45 | 1050 | 476 | 775 | 351 |

| 9 | 2.74 | 950 | 431 | 675 | 306 |

| 10 | 3.05 | 850 | 385 | 650 | 295 |

| 11 | 3.35 | 700 | 317 | 550 | 250 |

| 12 | 3.66 | 550 | 250 | 450 | 204 |

| 13 | 3.96 | 500 | 226 | 385 | 175 |

| 14 | 4.27 | 435 | 197 | 300 | 136 |

| 15 | 4.57 | 350 | 159 | 250 | 113 |

| 16 | 4.88 | 335 | 152 | 250 | 113 |

| 17 | 5.18 | 280 | 127 | 175 | 79 |

| 18 | 5.48 | 265 | 120 | 175 | 79 |

| 19 | 5.79 | 230 | 104 | 150 | 68 |

| 20 | 6.10 | 210 | 95 | 150 | 68 |

| 21 | 6.40 | 195 | 88 | 125 | 57 |

| 22 | 6.70 | 175 | 79 | 125 | 57 |

| 23 | 7.01 | 160 | 73 | 125 | 57 |

| 24 | 7.31 | 145 | 66 | 100 | 57 |

*Due to Ergonomic considerations, each rail span distance is tested to determine the maximum single point load required to achieve a predetermined deflection based on a ratio of 1:350 (1” of deflection for each 350” of length) or 1:450 (1” of deflection in 450” of length)

For purposes of estimating approximate ergonomic force requirements, the following

formula may be used:

Fs = frictional force = 0.009 x total mass. This indicates the maximum effort (in lbf) required to overcome inertia. Effort required to sustain movement, Fk (dynamic friction force) is generally 0.35 times the frictional force.

E.g.;

Fs = 0.009 x 250 lbs. (113.4 kg) mass = 2.25 lbf (0.9 kg) required to overcome inertia.

Fk = 0.009 x 250 lbs. (113.4 kg) mass x .35 = .79 lbf (0.36 kg) required to sustain movement.

Cantilevered Capacities (based on an optimum 8ft. hanger span)

| Cantilevered | Deflection Criteria | ||||||

|---|---|---|---|---|---|---|---|

| 1:350 Capacity* | 1:450 Capacity* | ||||||

| ft | m | lbs | kg | lbs | kg | ||

| 1 | .30 | 900 | 408 | 750 | 340 | ||

| 2 | .61 | 325 | 147 | 300 | 136 | ||

| 3 | .91 | 125 | 57 | 100 | 45 | ||

| 4 | 1.20 | 35 | 16 | 30 | 14 | ||

Elastic deformation: This type of deformation is reversible. Once the forces are removed, the object returns to its original shape. The elastic range ends when the material reaches its yield strength. At this point deformation begins.

Plastic deformation: This type of deformation is not reversible. Once an object reaches this point, it will not return to its original shape. Plastic deformation ends with the fracture of the material.

Knight Global follows material handling industry standards in determining the capacity ratings for enclosed track overhead workstation crane systems. Each component (e.g. rail, hangers, trolleys,etc.) is individually tested to establish its ultimate failure point. From this number, a safe working load is then assigned to the component. Each rail span length is then tested to determine the maximum single point load required to achieve a predetermined deflection based on a 1:350 ratio (1″ of deflection for each 350″ of length). The recommended rated capacity chart is based upon single point loading for the listed spans.

RAD6110 Capacity Chart

+Rail Capacities

| Hanger Span | Deflection Criteria | ||||

|---|---|---|---|---|---|

| 1:350 Capacity* | 1:450 Capacity* | ||||

| ft | m | lbs | kg | lbs | kg |

| 5 | 1.52 | 1600 | 725 | 1300 | 590 |

| 6 | 1.83 | 1600 | 725 | 1300 | 590 |

| 7 | 2.13 | 1500 | 680 | 1175 | 533 |

| 8 | 2.45 | 1475 | 699 | 1075 | 488 |

| 9 | 2.74 | 1400 | 635 | 1025 | 465 |

| 10 | 3.05 | 1325 | 601 | 925 | 453 |

| 11 | 3.35 | 1100 | 499 | 875 | 397 |

| 12 | 3.66 | 950 | 431 | 750 | 340 |

| 13 | 3.96 | 825 | 374 | 650 | 295 |

| 14 | 4.27 | 750 | 340 | 575 | 261 |

| 15 | 4.57 | 675 | 306 | 515 | 233 |

| 16 | 4.88 | 600 | 272 | 470 | 213 |

| 17 | 5.18 | 525 | 238 | 405 | 184 |

| 18 | 5.48 | 450 | 204 | 350 | 159 |

| 19 | 5.79 | 425 | 193 | 325 | 147 |

| 20 | 6.10 | 400 | 181 | 300 | 136 |

| 21 | 6.40 | 360 | 163 | 275 | 125 |

| 22 | 6.70 | 320 | 145 | 250 | 113 |

| 23 | 7.01 | 285 | 129 | 210 | 95 |

| 24 | 7.31 | 245 | 111 | 185 | 84 |

*Due to Ergonomic considerations, each rail span distance is tested to determine the maximum single point load required to achieve a predetermined deflection based on a ratio of 1:350 (1” of deflection for each 350” of length) or 1:450 (1” of deflection in 450” of length).

For purposes of estimating approximate ergonomic force requirements, the following

formula may be used:

Fs = frictional force = 0.009 x total mass. This indicates the maximum effort (in lbf) required to overcome inertia. Effort required to sustain movement, Fk (dynamic friction force) is generally 0.35 times the frictional force.

E.g.;

Fs = 0.009 x 250 lbs. (113.4 kg) mass = 2.25 lbf (0.9 kg) required to overcome inertia.

Fk = 0.009 x 250 lbs. (113.4 kg) mass x .35 = .79 lbf (0.36 kg) required to sustain movement.

Cantilevered Capacities (based on an optimum 8ft. hanger span)

| Cantilevered | Deflection Criteria | ||||||

|---|---|---|---|---|---|---|---|

| 1:350 Capacity* | 1:450 Capacity* | ||||||

| ft | m | lbs | kg | lbs | kg | ||

| 1 | .30 | 2200 | 998 | 1700 | 771 | ||

| 2 | .61 | 1000 | 454 | 775 | 351 | ||

| 3 | .91 | 600 | 272 | 475 | 215 | ||

| 4 | 1.20 | 250 | 113 | 125 | 57 | ||

RAD7510 Capacity Chart

+Rail Capacities

| Hanger Span | Deflection Criteria | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RAD7510 Series | RAD7510 + 6″ Backer | RAD7510 + 8″ Backer | |||||||||||

| 1:350 Capacity* | 1:450 Capacity* | 1:350 Capacity* | 1:450 Capacity* | 1:350 Capacity* | 1:450 Capacity* | ||||||||

| ft | m | lbs | kg | lbs | kg | lbs | kg | lbs | kg | lbs | kg | lbs | kg |

| 5 | 1.52 | 3000 | 1360 | 2700 | 1225 | 12170 | 5520 | 12170 | 5520 | 16355 | 7418 | 16355 | 7418 |

| 6 | 1.83 | 3000 | 1360 | 2700 | 1225 | 10130 | 4595 | 10130 | 4595 | 13620 | 6178 | 13620 | 6178 |

| 7 | 2.13 | 3000 | 1360 | 2700 | 1225 | 8670 | 3933 | 8670 | 3933 | 11660 | 5289 | 11660 | 5289 |

| 8 | 2.45 | 3000 | 1360 | 2700 | 1225 | 7575 | 3436 | 7575 | 3436 | 10190 | 4622 | 10190 | 4622 |

| 9 | 2.74 | 2700 | 1225 | 2400 | 1088 | 6720 | 3048 | 6720 | 3048 | 9045 | 4103 | 9045 | 4103 |

| 10 | 3.05 | 2500 | 1134 | 2000 | 907 | 6035 | 2737 | 6035 | 2737 | 8130 | 3688 | 8130 | 3688 |

| 11 | 3.35 | 2500 | 1134 | 1900 | 862 | 5475 | 2483 | 5475 | 2483 | 7375 | 3345 | 7375 | 3345 |

| 12 | 3.66 | 2500 | 1134 | 1800 | 816 | 5010 | 2272 | 5010 | 2272 | 6750 | 3062 | 6750 | 3062 |

| 13 | 3.96 | 2000 | 907 | 1800 | 816 | 4610 | 2091 | 4610 | 2091 | 6215 | 2819 | 6215 | 2819 |

| 14 | 4.27 | 2000 | 907 | 1500 | 680 | 4270 | 1937 | 4270 | 1937 | 5760 | 2613 | 5760 | 2613 |

| 15 | 4.57 | 1900 | 861 | 1500 | 680 | 3975 | 1803 | 3975 | 1803 | 5365 | 2434 | 5365 | 2434 |

| 16 | 4.88 | 1800 | 816 | 1200 | 544 | 3710 | 1683 | 3710 | 1683 | 5015 | 2275 | 5015 | 2275 |

| 17 | 5.18 | 1700 | 771 | 1200 | 544 | 3480 | 1578 | 3480 | 1578 | 4750 | 2134 | 4750 | 2134 |

| 18 | 5.48 | 1600 | 726 | 1000 | 453 | 3275 | 1486 | 3275 | 1486 | 4430 | 2009 | 4430 | 2009 |

| 19 | 5.79 | 1450 | 658 | 1000 | 453 | 3090 | 1402 | 3090 | 1402 | 4185 | 1898 | 4185 | 1898 |

| 20 | 6.10 | 1300 | 590 | 900 | 408 | 2925 | 1327 | 2925 | 1327 | 3965 | 1798 | 3965 | 1798 |

| 21 | 6.40 | 1100 | 499 | 900 | 408 | 2775 | 1259 | 2535 | 1550 | 3760 | 1705 | 3760 | 1705 |

| 22 | 6.70 | 900 | 408 | 800 | 363 | 2635 | 1195 | 2285 | 1036 | 3575 | 1622 | 3560 | 1615 |

| 23 | 7.01 | 900 | 408 | 700 | 317 | 2510 | 1139 | 2070 | 939 | 3410 | 1547 | 3230 | 1465 |

| 24 | 7.31 | 885 | 402 | 700 | 317 | 2390 | 1084 | 1880 | 853 | 3255 | 1476 | 2945 | 1336 |

| 25 | 7.62 | 850 | 386 | 700 | 317 | 2250 | 1021 | 1710 | 776 | 3110 | 1411 | 2690 | 1220 |

| 26 | 7.92 | 725 | 329 | 700 | 317 | 2060 | 934 | 1555 | 705 | 2980 | 1352 | 2465 | 1118 |

| 27 | 8.23 | 725 | 329 | 675 | 306 | 1890 | 857 | 1420 | 644 | 2855 | 1295 | 2260 | 1025 |

| 28 | 8.53 | 600 | 272 | 550 | 250 | 1735 | 787 | 1300 | 590 | 2735 | 1241 | 2075 | 941 |

| 29 | 8.83 | 600 | 272 | 550 | 250 | 1595 | 723 | 1190 | 540 | 2525 | 1145 | 1910 | 866 |

*Due to Ergonomic considerations, each rail span distance is tested to determine the maximum single point load required to achieve a predetermined deflection based on a ratio of 1:350 (1” of deflection for each 350” of length) or 1:450 (1” of deflection in 450” of length).

For purposes of estimating approximate ergonomic force requirements, the following

formula may be used:

Fs = frictional force = 0.009 x total mass. This indicates the maximum effort (in lbf) required to overcome inertia. Effort required to sustain movement, Fk (dynamic friction force) is generally 0.35 times the frictional force.

E.g.;

Fs = 0.009 x 250 lbs. (113.4 kg) mass = 2.25 lbf (0.9 kg) required to overcome inertia.

Fk = 0.009 x 250 lbs. (113.4 kg) mass x .35 = .79 lbf (0.36 kg) required to sustain movement.

Cantilevered Capacities (based on an optimum 8ft. hanger span)

| Cantilevered | Deflection Criteria | ||||||

|---|---|---|---|---|---|---|---|

| 1:350 Capacity* | 1:450 Capacity* | ||||||

| ft | m | lbs | kg | lbs | kg | ||

| 1 | .30 | 3000 | 1361 | 2700 | 1225 | ||

| 2 | .61 | 2200 | 998 | 2000 | 907 | ||

| 3 | .91 | 900 | 408 | 775 | 352 | ||

| 4 | 1.20 | 375 | 170 | 325 | 147 | ||

RAD8110 Capacity Chart

+Rail Capacities

| Hanger Span | Deflection Criteria | ||||

|---|---|---|---|---|---|

| 1:350 Capacity* | 1:450 Capacity* | ||||

| ft | m | lbs | kg | lbs | kg |

| 5 | 1.52 | 4000 | 1814 | 4000 | 1814 |

| 6 | 1.83 | 3575 | 1622 | 3575 | 1622 |

| 7 | 2.13 | 3060 | 1388 | 3060 | 1388 |

| 8 | 2.45 | 2670 | 1211 | 2670 | 1211 |

| 9 | 2.74 | 2370 | 1075 | 2370 | 1075 |

| 10 | 3.05 | 2130 | 966 | 2130 | 966 |

| 11 | 3.35 | 1925 | 873 | 1925 | 873 |

| 12 | 3.66 | 1760 | 798 | 1760 | 798 |

| 13 | 3.96 | 1620 | 735 | 1400 | 635 |

| 14 | 4.27 | 1500 | 680 | 1200 | 544 |

| 15 | 4.57 | 1340 | 608 | 1030 | 467 |

| 16 | 4.88 | 1165 | 528 | 895 | 406 |

| 17 | 5.18 | 1020 | 463 | 780 | 354 |

| 18 | 5.48 | 900 | 408 | 685 | 311 |

| 19 | 5.79 | 800 | 363 | 605 | 274 |

| 20 | 6.10 | 710 | 322 | 535 | 243 |

| 21 | 6.40 | 630 | 286 | 470 | 213 |

| 22 | 6.70 | 560 | 254 | 420 | 191 |

| 23 | 7.01 | 500 | 227 | 370 | 168 |

| 24 | 7.31 | 450 | 204 | 330 | 150 |

*Due to Ergonomic considerations, each rail span distance is tested to determine the maximum single point load required to achieve a predetermined deflection based on a ratio of 1:350 (1” of deflection for each 350” of length) or 1:450 (1” of deflection in 450” of length).

For purposes of estimating approximate ergonomic force requirements, the following

formula may be used:

Fs = frictional force = 0.009 x total mass. This indicates the maximum effort (in lbf) required to overcome inertia. Effort required to sustain movement, Fk (dynamic friction force) is generally 0.35 times the frictional force.

E.g.;

Fs = 0.009 x 250 lbs. (113.4 kg) mass = 2.25 lbf (0.9 kg) required to overcome inertia.

Fk = 0.009 x 250 lbs. (113.4 kg) mass x .35 = .79 lbf (0.36 kg) required to sustain movement.

Videos

+*Air Glide Hose Management System

*Applications Compilation

End Trucks – Single / Dual / Rigid

Medium Duty Aluminum Rail

Rail Inspection / Access Gate

Accessories

General

+Hangers

+Load Trolleys

+End Trucks

+End Caps / Stops

+Safety Cables

+Access Gates

+Splice Kits

+Hose Management

+Hose Trolleys

+