Engineered Aluminum Rail Series

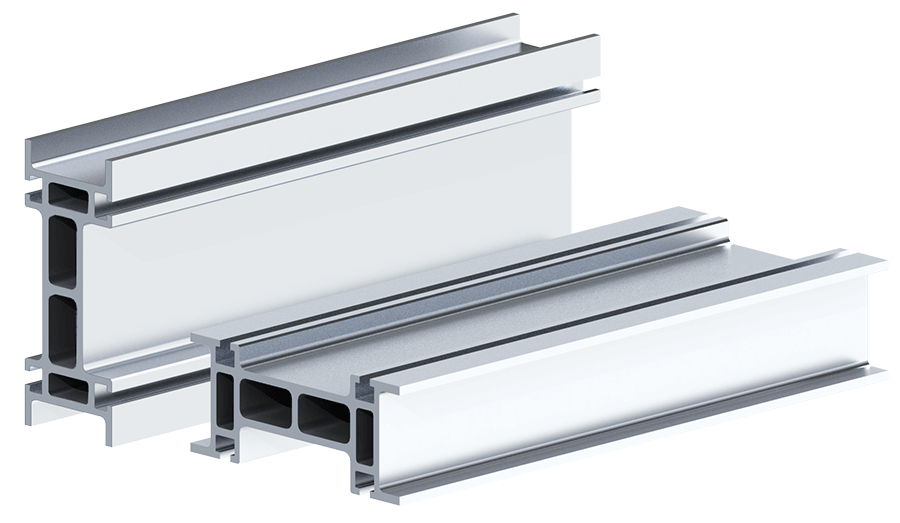

Knight’s HAD3000 Engineered Aluminum Rail Series has a Chambered Rail design that is extruded from a lightweight, high-strength aluminum alloy. The lightweight aluminum rail eases installation and reduces overhead requirements. The HAD3000 Series Rail is the ideal solution for light duty applications, work benches and stations, festooning management and light fixtures. This series can also be used as a fluid power distribution system for non-caustic fluids and can serve as a manifold, providing more CFM to pneumatic powered tools when compared to black pipe.

The HAD3500 Series Rail can also be used for light duty applications, such as weld guns, work benches and stations, festooning management and light fixtures. This series, combined with nylon trolley wheels, provides the lowest friction in the industry.

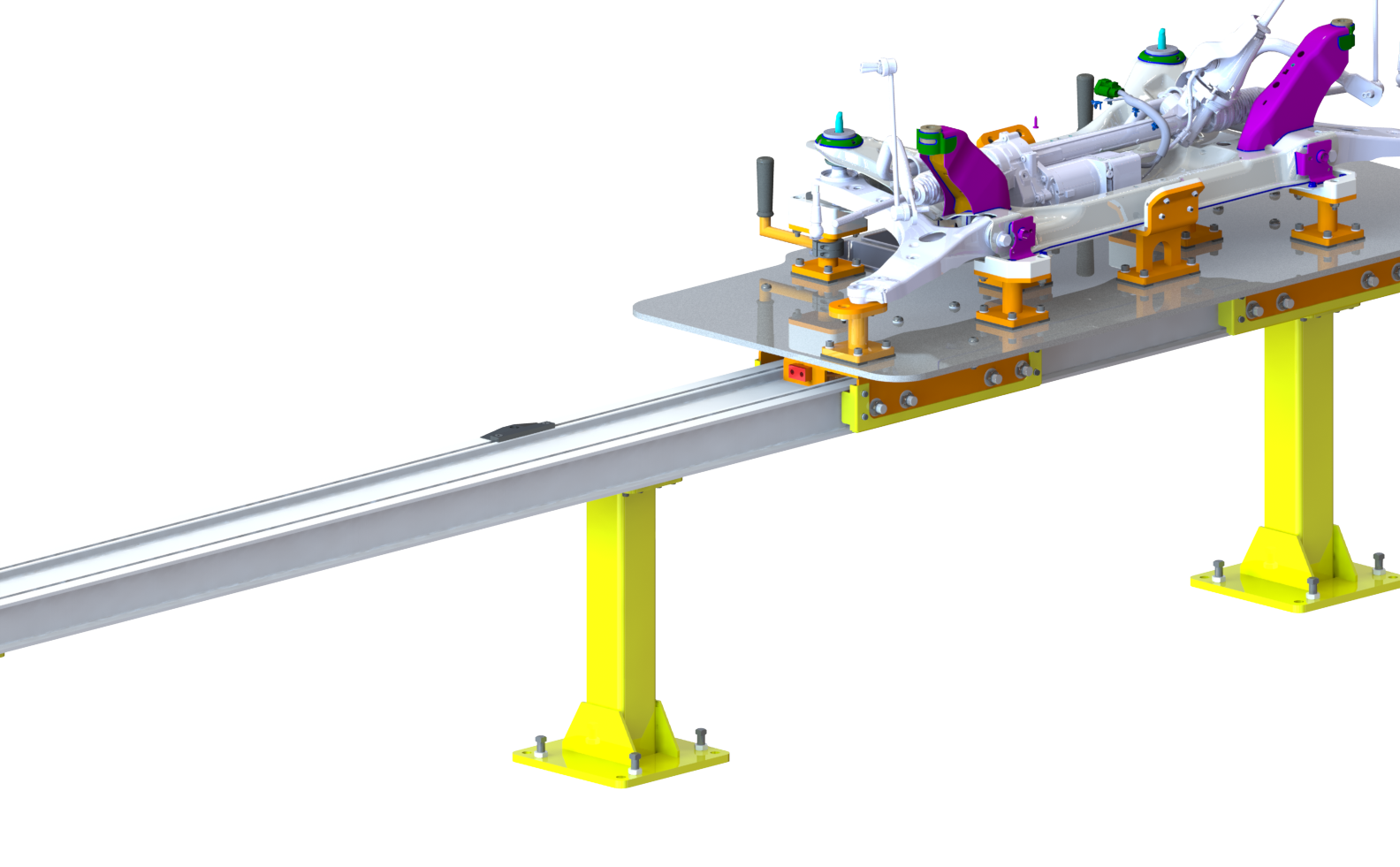

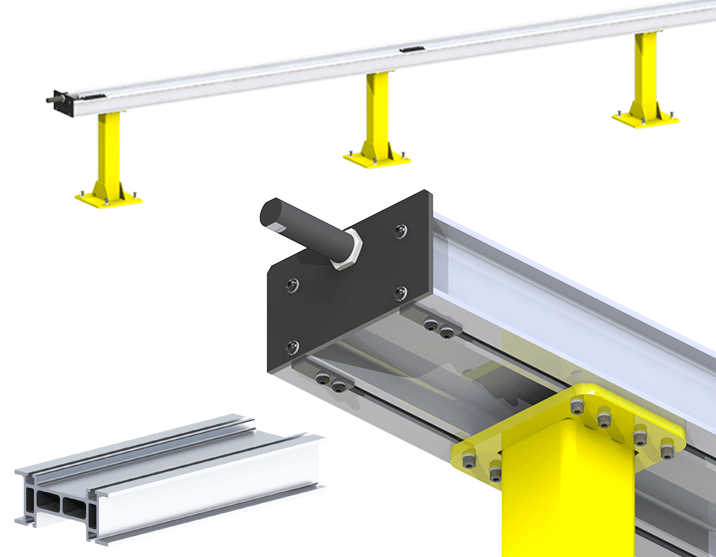

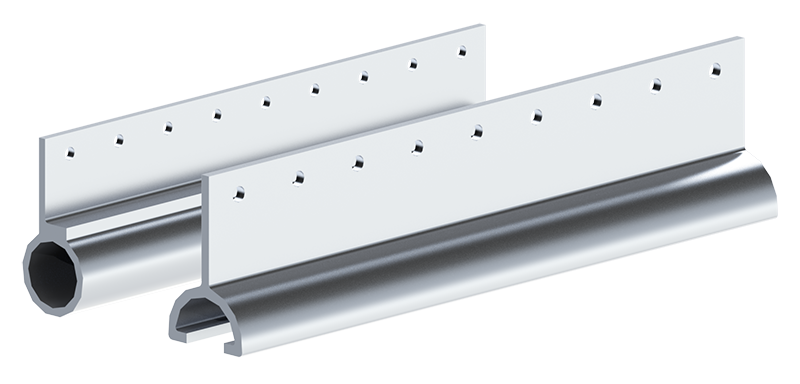

The LRD9500 Engineered Aluminum Linear Rail is for post-mounted or floor-mounted applications that require low friction horizontal movements. It is capable of handling direct and offset loads. Linear engineered rail is a lower maintenance alternative to hardened ground rail and bearings blocks. Linear rail is most often mounted in horizontal configurations using carriage mounted pneumatic arms.

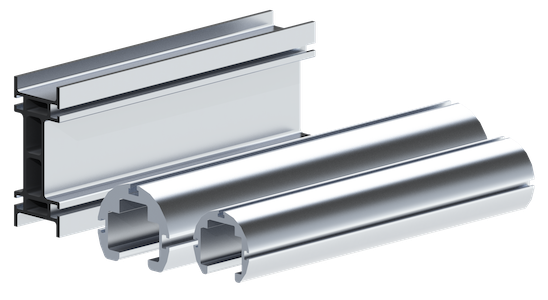

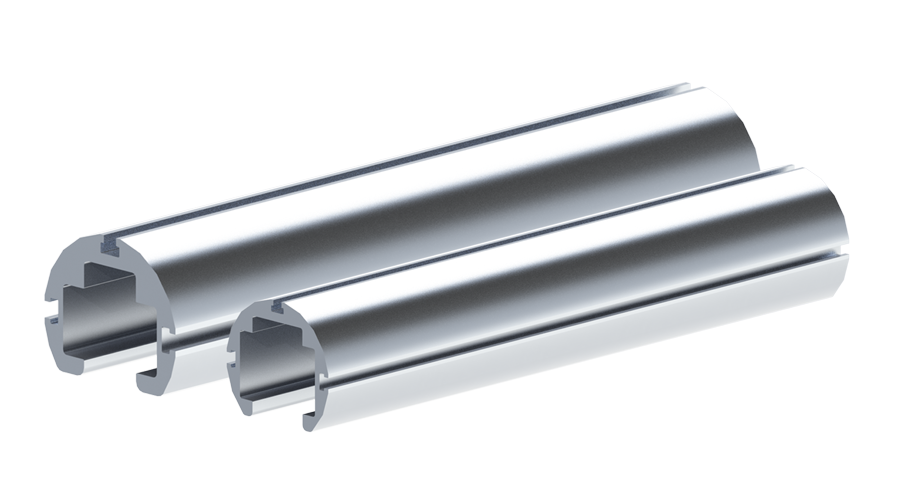

The RAD4700 and RAD6500 Engineered Round Rail Series is for low friction vertical or horizontal linear movements. It is capable of handling direct or offset loads as well as high torque applications. Round rail is designed to be more ergonomically friendly when compared to traditional linear motion products. Capacities are usually based by application.

General Information

+Engineered Aluminum Rail Series

| Series | Max. Capacity | Product Weight |

|---|---|---|

| HAD3000 | 125 lbs. [56kg] | 3.3 lbs/ ft. [1.50kg/m] |

| HAD3500 | 125 lbs. [56kg] | 2.6 lbs/ ft. [1.18kg/m] |

| LRD9500 | 300 lbs. [136kg] | 9.8 lbs/ ft. [4.45kg/m] |

HAD3000 Series

+Features

- Mechanical Properties: ASTM B221 6005-T5 Series Aluminum.

- Overhead and Floor Mounted Configurations.

- Supports Trolleys.

- Pre-Drilled Ports every: 5 ft. [1.3m].

- NPT Air Outlet Connector: 3/8 in. [9.5mm] or 1/2 in. [12.7mm].

- NPT Plant Air Inlet Connector: 1 in. [25mm].

- Up to 600 psi when used for Fluid/ Air.

Benefits

- Rail Lengths: Up to 20 ft. [6m].

- Multiple Pre-Assembled Accessories.

- Can be used as a Fluid Power Distribution System and a Pneumatic CFM Manifold System.

- Easy Maintenance.

- Simple Installation:

- No Welding or Grinding.

- Modular Connections to Structural Supports.

- Modular Connections between Sections.

HAD3500 Series

+Features

- Mechanical Properties: ASTM B221 6005-T5 Series Aluminum.

- Overhead and Floor Mounted Configurations.

- Supports Trolleys.

Benefits

- Rail Lengths: Up to 20 ft. [6m].

- Multiple Pre-Assembled Accessories.

- Can be used as a Fluid Power Distribution System and a Pneumatic CFM Manifold System.

- Easy Maintenance.

- Simple Installation:

- No Welding or Grinding.

- Modular Connections to Structural Supports.

- Modular Connections between Sections.

LRD9500 Series

+Features

- Mechanical Properties: ASTM B221 6005-T5 Series Aluminum.

- Floor Mounted Post Configurations.

- Supports carriages and pneumatic arms.

Benefits

- Multiple Pre-Assembled Accessories.

- Carriages are designed for cantilevered and direct load applications.

HAD3000 and HAD3500 Capacities

+HAD3000 & HAD3500 Capacities

| Hanger Span | Deflection Criteria | ||||||

|---|---|---|---|---|---|---|---|

| 1:350 Capacity | 1:450 Capacity | ||||||

| ft | m | lbs | kg | lbs | kg | ||

| 5 | 1.52 | 125 | 57 | 125 | 57 | ||

| 6 | 1.83 | 125 | 57 | 125 | 57 | ||

| 7 | 2.13 | 125 | 57 | 125 | 57 | ||

| 8 | 2.45 | 125 | 57 | 125 | 57 | ||

| 9 | 2.74 | 125 | 57 | 125 | 57 | ||

| 10 | 3.05 | 125 | 57 | 125 | 57 | ||

| 11 | 3.35 | 125 | 57 | 122 | 56 | ||

| 12 | 3.66 | 125 | 57 | 104 | 47 | ||

| 13 | 3.96 | 125 | 57 | 84 | 38 | ||

| 14 | 4.27 | 125 | 57 | 77 | 35 | ||

| 15 | 4.57 | 125 | 57 | 70 | 31 | ||

| 16 | 4.88 | 125 | 57 | 60 | 27 | ||

| 17 | 5.18 | 113 | 51 | 54 | 24 | ||

| 18 | 5.49 | 100 | 45 | 52 | 23 | ||

| 19 | 5.79 | 91 | 41 | 46 | 20 | ||

| 20 | 6.10 | 82 | 37 | 11 | 19 | ||

LRD9500 Capacities

+LRD9500 Capacities

| Linear Ergo Forces | |||||||

|---|---|---|---|---|---|---|---|

| 50 Lbs. Push/Pull | 100 Lbs Push/Pull. | 150 Lbs. Push/Pull | 200 Lbs. Push/Pull | ||||

| 3.97 lbs. ft. | 6.33 lbs. ft. | 7.10 lbs. ft. | 10.46 lbs. ft. | ||||

Videos

+*Bolt Secure Assists on Linear Rail

*Custom Linear Rail System – Fuel Tank Load

*Suspension Build-Up Table on Linear Rail

Linear Rail ERM Install

Linear Rail Nut Runner

Linear Rail Range of Motion

Accessories

General

+Load Trolleys

+End Caps / Stops

+Splice Kits

+