End Effectors

Knight Global designs and builds an assortment of custom End Effectors, specializing in custom lift assists and lifting devices, for all of your ergonomic solutions. From the simplest applications to the most complicated, we’ll assist you in choosing the correct End Effector that is best suited to meet your manufacturing needs.

There are five (5) design styles of End Effectors that include: Clamp, Hook, Magnet, Nest, and Vacuum. Each handling device is designed with the operator’s safety in mind. End effectors can be operated manually, mechanically or powered to meet your application requirements.

Our team of fixture designers will create a detailed, ergonomic analysis of your material handling needs, which is the most important step in being able to suit you with the correct assist device. We factor in every aspect of your application, from the environment, desired operation, overall clearances, product materials and surfaces, clamp locations, required movements (angles/tilts/ turns/rotations), cycle times, to the set-down environment.

Clamp

+

Clamp End Effector/End Tooling

Clamp End Effectors are available in an inner and outer surface clamp configuration, and an inner and outer diameter clamp configuration. Clamp end effectors are used to handle a wide variety of applications. Clamp End Effectors apply inner or outer force to secure the product and are designed specifically to each application.

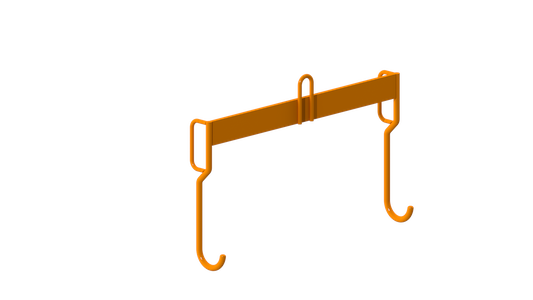

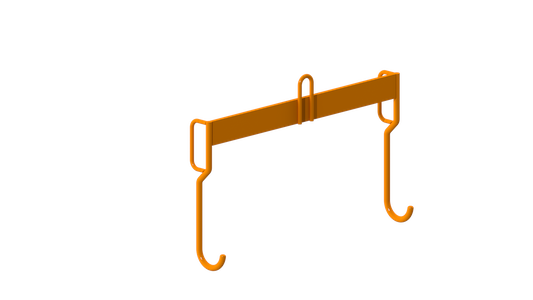

Hook

+ Hook End Effector/End Tooling

Hook End Effector/End Tooling

Hook End Effectors are designed to be a quick and simple solution when available to transfer your product and are available in multiple styles. Hook End Effectors quickly connect and disconnect to designated areas of the product or fixture. Most applications tend to be straight lift and transfer with no manipulation of the product. Some typical applications include: spare tire transfers, hood lifts, cylinder head lifts, axle lifts, driveshafts and battery lifts.

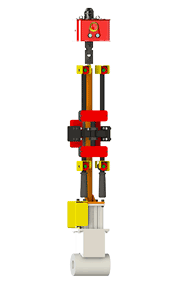

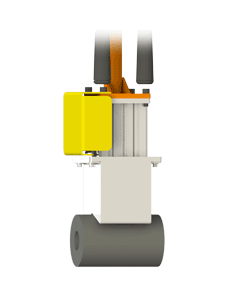

Magnet

+ Magnet End Effector/End Tooling

Magnet End Effector/End Tooling

Magnet End Effectors are ideal for steel parts. Standard Magnet End Effectors are available in an Air Driven or Electromagnet configuration depending on your application. Magnet End Effectors are commonly used for picking up sheets of steel or cylindrical steel tubes among many other types of applications. Magnet manipulators maximum capacities vary per application.

Nest

+ Nest End Effector/End Tooling

Nest End Effector/End Tooling

Nest End Effectors are an ideal for less-complex, but secure solutions. These devices are used to handle a wide variety of applications that require no part manipulation. Nest End Effectors scoop underneath the product using it weight and gravity to secure the product being transferred. A latch or clamp may be added to secure the part into the fixture. The nesting structure can be brass, steel, urethane, nylon, etc. Nest End Effectors are easy to operate and require little to no maintenance.

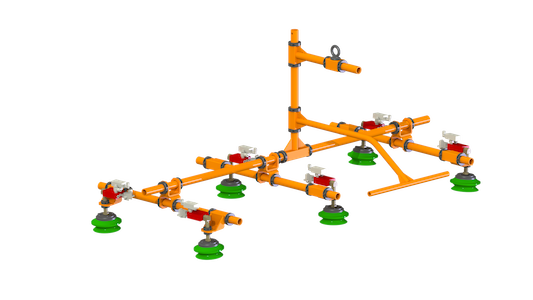

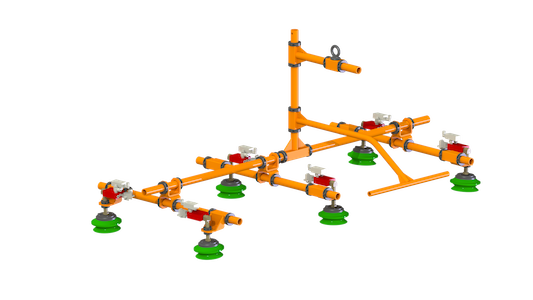

Vacuum

+ Vacuum End Effector/End Tooling

Vacuum End Effector/End Tooling

Vacuum Cup End Effectors are an ideal solution for handling non and low porous materials with flat or slightly curved surfaces such as metal sheets, glass, boxes, hoods, doors, body panels, etc. Vacuum End Effectors are available in multiple cup configurations depending on the application requirement. Vacuum manipulators are commonly used for straight, horizontal, shear and multi-contoured surface transfers. The maximum capacity of Vacuum End Effectors varies per application.

Videos

+*Applications Compilation

*Extension Arm – Hood Lift Assist

Clamp End Effectors Compilation

Cross Member Lift Assist

Custom Exhaust End Effector Lift Assist to Dunnage

Custom Front Seat End Effector

Custom Wheel Weight Install End Effector

Engine Flywheel Install Using Custom End Effector

Extension Servo Arm Rear Tire Install Assist

Front Vehicle Cab Lift Assist with Custom End Effector

Hook End Effectors Compilation

KSH Servo Hoist Engine Oil Pan Lift Assist

Linear Rail Nut Runner

Magnet End Effectors Compilation

Nest End Effectors Compilation

Rear Axle Scissor Clamp End Effector

Servo Hoist Ring Gear Lift & Rotate Assist

Steel Plate End Effector Lift Assist

Suspension Lift Assist

Vacuum End Effectors Compilation

Vehicle Axle Lift and Rotate Assist

Vertical Torque Arm – A/C Unit Lift Assist