Servo Tractors

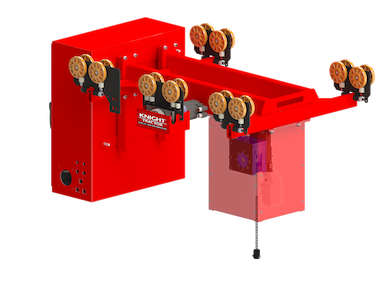

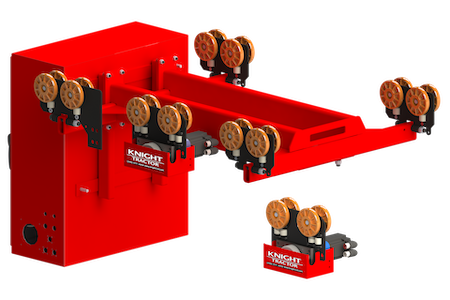

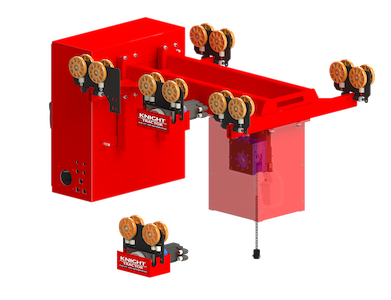

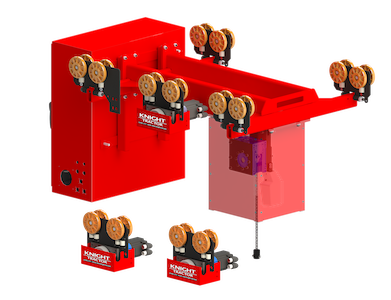

Knight’s Servo Tractors are designed to accurately locate, push, tow, lift and position loads from an overhead rail system. Tractors significantly reduce the push/pull forces as well as the energy to sustain movements.

These Servo Tractors are equipped with Knight’s (IAD) Intelligent Assist Device Servo Technology, allowing them to provide controlled transfers of workloads with speed and precision. They can be programmed to automatically or manually move and stop the runway at intended locations with repeatable accuracy while lifting loads at the same time; thus eliminating unnecessary operator motions. They can also be programmed for assembly line speed synchronization.

The KST4000 Rack and Pinion Servo Tractor offers a continuous contact non-slip rack and pinion design. This continuous non-slip design allows for a more accurate positioning of the load. Movement of the Servo Tractor is controlled by a two speed pendant, and can be programmed for multiple positions.

General Information

+Mechanical

- Variable Maximum Speed: Up to 174 ft. per min. [53.2mpm].

- Maximum Towing Capacity: Up to 4,000 lbs. [1,814.37kg].

- Maximum Lifting Capacity: Up to 1,000 lbs. [453.59kg].

- Non-Slip Rack and Pinion Drive System.

- Clutch (24 VDC).

- Power and Free Drive Wheel.

- Absolute Positioning.

- Safety Rating of 125%.

- Fail Safe Brake.

- Knight’s Patented Chain, for longer life.

- Chain Lengths, Unlimited (18 ft. Standard).

- Sealed Worm Style Gearbox.

Software

- Programming and Diagnostic Communication Ports.

- Virtual Travel Limits.

- Speed Reduction Zones.

- Impact Limiting.

- Active Dampening.

- Standard Float Mode.

- Programmable Overload Capability.

Electrical

- Industry Standard 24 VDC, 2 AMP power is available for custom tooling such as: Clamps, Vacuum Cups, Switches, Proximity Limits, Lights, etc.

- H5 Rated (Continuous Duty Cycle).

- 240VAC, Single Phase, 50/60 Hz.

- Load Sensing, Pay Load and Handle Load.

- I/O Capabilities:

– (16) Inputs/ (8) Outputs

– (8) Inputs/ (4) Outputs are free for interface controls. - LED Status Indicators, Green and Blue Lighted Push buttons.

- LED Fault Indicators, Illuminated Run/ Stop Button, Twist to Release.

- Optional Remote Pendant or Wireless Remote Control.

Axis Direction Options

- Rack and Pinion Tractor

- “X” Tractor w/”Z” Control

- “X/Y” Tractor

- “X/Y” Tractor w/”Z” Control

- “XX/Y” Tractor w/”Z” Control

Servo Tractor Series Specifications

+KST4000 Rack and Pinion Tractor Series

| Towing Capacity lbs. [kg] | Max. Speed [fpm/mpm] |

|---|---|

| 4,000 [1,814.37] | 261.8 fpm. [79mpm] |

| 4,000 [1,814.37] | 174.53 fpm. [53.2mpm] |

KSHXZ/ KSHXY/ KSHXYZ/ KSHXXYZ Servo Tractor Series

| Hoist Capacity lbs. [kg] | Towing Capacity lbs. [kg] | Hoist Lift Speed [fpm.] | Tractor Travel Speed [fpm.] |

|---|---|---|---|

| 250 lbs. [113.40kg] | 4,000 lbs. [1,814.37kg] | 196.85 fpm. [60.0mpm] | 174.53 fpm. [53.2mpm] |

| 350 lbs. [158.75kg] | 4,000 lbs. [1,814.37kg] | 241.00 fpm. [73.5mpm] | 174.53 fpm. [53.2mpm] |

| 750 lbs. [340.19kg] | 4,000 lbs. [1,814.37kg] | 123.03 fpm. [37.5mpm] | 174.53 fpm. [53.2mpm] |

| 1,000 lbs. [453.59kg] | 4,000 lbs. [1,814.37kg] | 82.02 fpm. [25.0mpm] | 174.53 fpm. [53.2mpm] |

Videos

+*Applications Compilation

*Servo Hoist XYZ System – Seat Install

*XY Servo System – Lift Gate

*XYZ Servo System – IP Install

Automated Servo – Transfer Case Lift Assist

Servo Hoist and Tractor Engine Lift Assist

Servo Hoist and Tractor Engine Transfer

Accessories