Torque Tubes

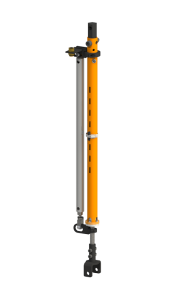

Knight’s NEWEST DESIGN of Torque Tubes are made to reduce operator fatigue by absorbing torque reaction produced by assembly tools while balancing the tool weight. The new style is more ROBUST and PRECISE while still maintaining a lighter and smoother operation than previous designs. They feature a linear bearing spline for effortless travel with zero rotational movement. Torque Tubes use a pneumatic cylinder or spring balancer to achieve zero gravity balancing. Each pneumatic cylinder is supplied with a single balance control.

Torque Tubes are most commonly used as tool holders by incorporating Knight’s ASA9519 360 degree Rotating Tool Clamp or Knight’s ASA9523 and ASA9524 Adjustable Fixed Tool Clamps.

Torque Tubes

+

Light Torque Tubes

Torque Tubes are ideal for small hand tools, pneumatic nut-runners and torque tools. Light-duty torque tubes have a maximum capacity of up to 35 lbs. [15kg].

Medium and Heavy Torque Tubes

Medium and Heavy Torque Tubes

These Torque Tubes are more commonly used for high torque producing tools and applications with custom designed tooling. Heavy Duty torque tubes have a maximum capacity of up to 500 lbs. [227kg].

Cylinder torque tubes are ideal in conditions where there is a need for the tool to remain in the same position after fastening. In other words, it remains balanced at any position in the vertical travel. Torque Tube safety cables (#RWA4133) are sold separately.

Spring Balancer

+

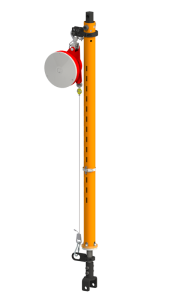

Spring Balancer Torque Tubes (Light/Medium Duty)

Knight Spring Balancers Torque Tubes can be used in various applications due to air not being a requirement for operation. Spring Balancer Torque Tubes are available in a light and medium duty configuration with a maximum capacity of up to 35 lbs. [15.8kg].

Spring Balancer torque tubes are ideal in conditions where there is a need for the tool to return to the full UP position after fastening. Torque Tube safety cables (#RWA4133) are sold separately.